- An Effective Mass Finishing Technology — Vibratory Deburring MachineThis Vibratory Deburring Machine is designed with a straight wall processing bowl, allowing for efficient and effective finishing of parts and components. The machine utilizes a vibratory motion to polish, deburr, clean, and surface finish a variety of materials. It is a cost-effective solution for mass finishing applications, and its compact design makes it easy to integrate into any production line.“I don’t know how to choose the Vibratory Deburring Machine and Vibratory Finishing Media.”Contact us here for more information and a free quote!

- Features>Heavy duty bowl welded from high quality steel>Cast polyurethane lining, not sprayed on>Powerful & Zero maintenance motor to increase productivity>Easy operation & reduced labor costs

- Technical Data

Model SW 30 SW 60 SW 80 Capacity(L/CuFt) 30 / 1.1 60 / 2.1 80 / 2.8 External Diameter Max. (mm/inch) 500 / 19.7 630 / 24.8 780 / 30.7 Process Bowl Width (mm/inch) 165 / 6.5 200 / 7.9 220 / 8.7 Process Bowl Depth (mm/inch) 190 / 7.5 240 / 9.4 250 / 9.8 Machine Height (mm/inch) 620 / 24.4 665 / 26.2 700 / 27.6 Motor Power & Speed (kW & rpm) 0.55& 1450 0.75 & 1450 1.1 & 1450 PU Thickness(mm/inch) 20-23/0.8-0.9 20-23/0.8-0.9 20-23/0.8-0.9 Weight(kg/lbs) 50 / 110.2 85 / 187.4 100 / 220.5 - Optional Settings

> Pneumatic Soundproof Cover

> Manual Soundproof Cover

>Spacials divider

> Control panels

>Speed controller

>Automatic liquid feeding system

Multi-faceted manufacturing processes

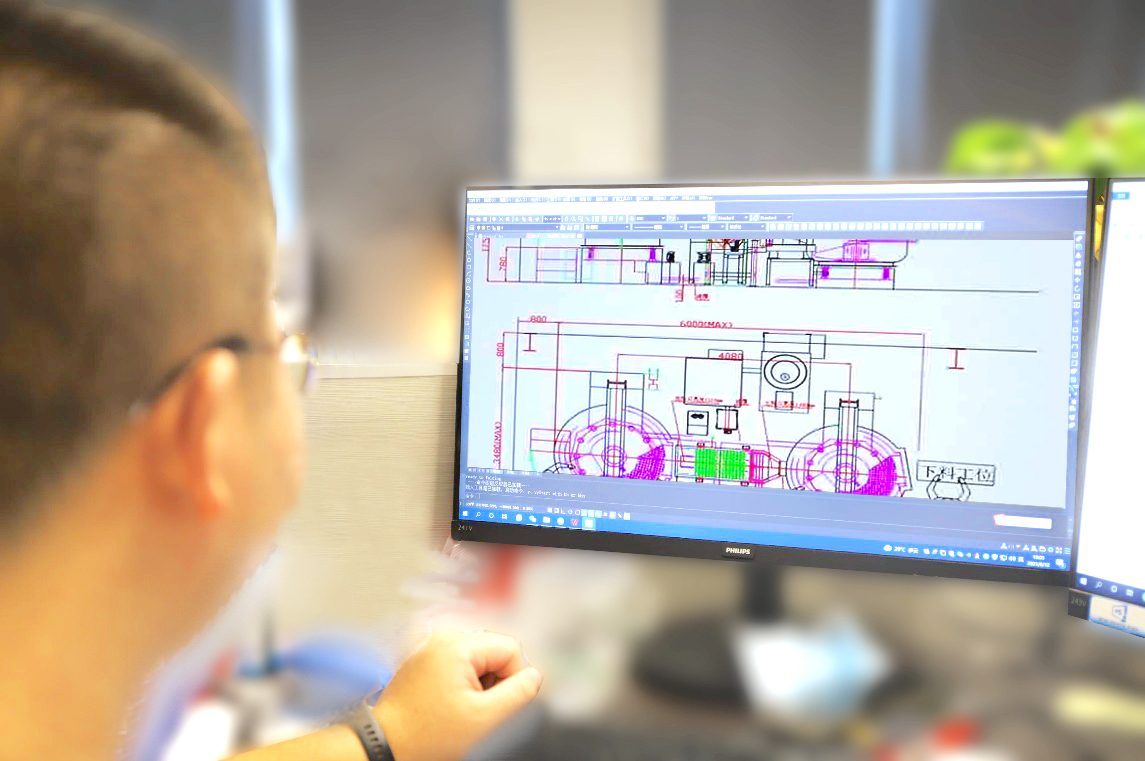

Mechanical Design: The journey begins with the creative minds at Mass Polishing conceptualizing and refining the mechanical design of their vibratory mass finishing machines. Through years of expertise and industry knowledge, their engineers meticulously craft designs that optimize functionality, durability, and efficiency. CAD Drawing Planning: Once the mechanical design is finalized, Mass Polishing’s team of skilled CAD designers transforms the concept into precise and detailed 3D computer-aided design (CAD) drawings. These drawings serve as the blueprint for every component, ensuring accurate manufacturing and assembly processes. CNC Machining: With the CAD drawings in hand, the manufacturing process shifts gears to Mass Polishing’s state-of-the-art CNC (Computer Numerical Control) machining center. This cutting-edge technology enables the precise fabrication of intricate parts and components with unparalleled accuracy, consistency, and repeatability.

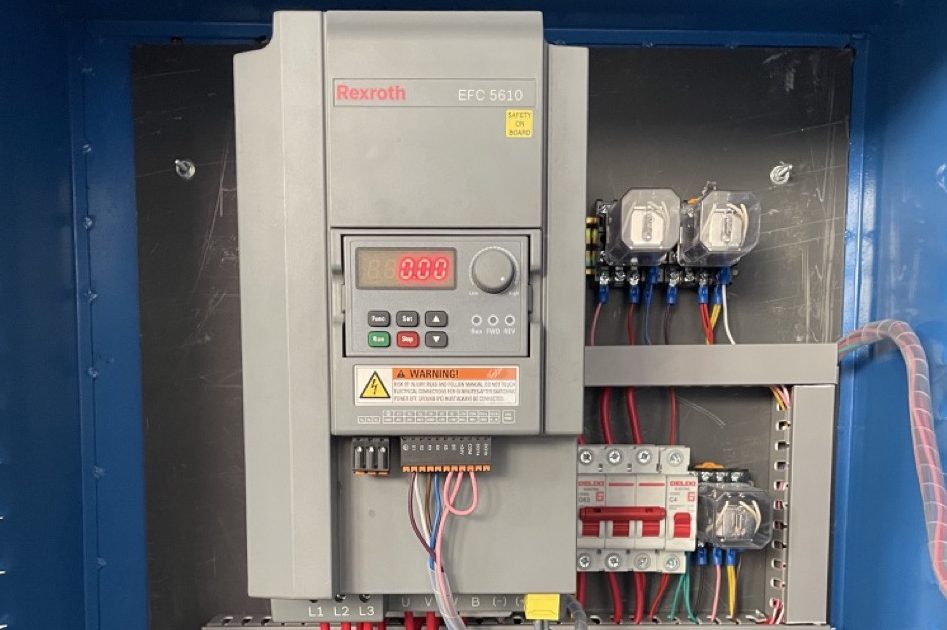

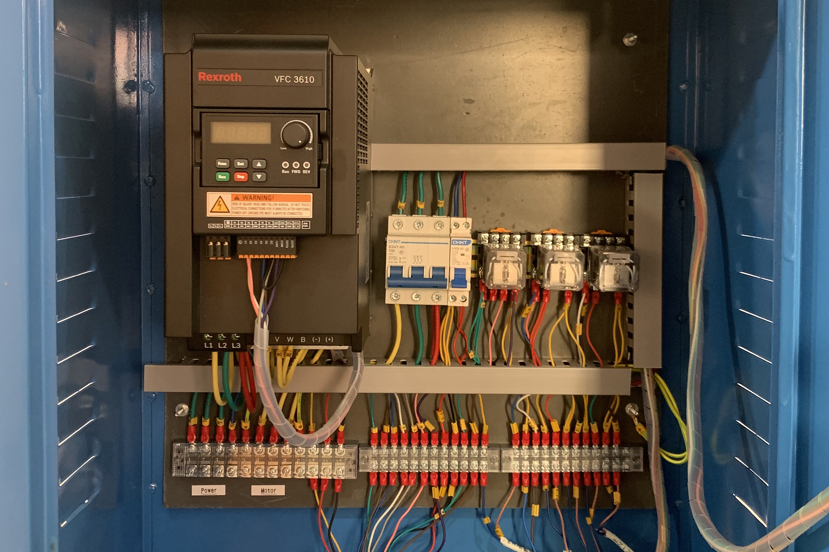

Laser Cutting: Mass Polishing harnesses the power of laser cutting to shape and refine various metal components. By utilizing high-powered lasers, they achieve clean and precise cuts, resulting in components that seamlessly integrate into the overall machine structure. PU Casting: To enhance the performance and durability of their machines, Mass Polishing employs polyurethane (PU) casting techniques. This process involves pouring liquid PU material into molds, which, when cured, forms robust and wear-resistant parts. The PU casting method ensures optimal noise reduction, extended machine lifespan, and superior finishing results. Electric Control Box: An integral aspect of every vibratory mass finishing machine, the electric control box is meticulously assembled and wired by Mass Polishing’s skilled technicians. The control box houses advanced electronic components, allowing for precise control and customization of the machine’s parameters, such as speed, time, and vibration intensity.

Be the first to review “30L 60L 80L Vibratory Deburring Machine” Cancel reply

Reviews

There are no reviews yet.